Vision

To become world leader in the field of carbon and graphite products by leveraging our core competence and by research and development on advanced materials.

Mission

HEG R&D Center for carbon science and technology will have strong applied research and development focus in the field of conventional carbon products and advanced carbon materials/ products such as carbon nanotubes/fibers.

It will push the technology envelope and shall establish a strong cooperative research effort (Industry / Government / University) to improve energy efficiency, process productivity and quality control of carbon products with environmentally responsible approach both in its operations and in its products that purify the environment. It shall develop new secure sources of high quality carbon feed stocks that can be used by a number of different carbon manufacturing processes and new carbon and graphite based products.

Activity Spectrum

The R&D Center is working on the following areas

- Advanced Materials/ Products

- Process Technology

- Carbon Specialities

- Material characterization

- Technical Library/ Archives

Infrastructure

A Separate R&D set up has been established by the company wherein the Scientists are working on Developmental projects as well as projects to sustain & improve the competitiveness of the company. Frequent Structured interactions are held between the Process Personnel & the R&D scientists to maintain the pace & momentum of the activities. The HEG R&D center has also entered into collaborations with reputed agencies like IIT ( Indian Institute of Technology) Kanpur, RRL ( Regional Research Laboratory, CSIR) Bhopal, CEFES (Center for Environment, Fire and Explosive Safety), New Delhi , etc.

The R&D Center is equipped with all major instruments necessary for graphite production, ranging from basic instruments for testing raw materials, measuring product properties to advanced characterization facilities required for understanding graphite up to higher research level.

Nitrogen Analyzer

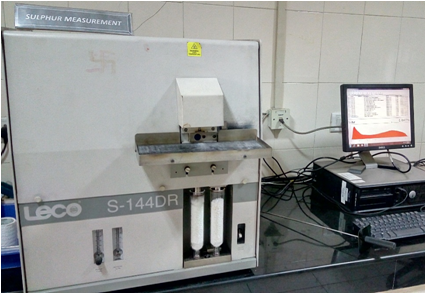

Sulphur Analyzer

Raw material property measurement facilities

- Real Density of CPC

- Bulk Density of CPC

- Electrical resistivity of CPC

- Coefficient of thermal expansion (CTE) of CPC

- Graphitization of metallurgical coke

- Compressibility & Elasticity of packing grain

- Pitch requirement of CPC

- Softening point of pitch

- Ash content in CPC

- Sulphur content in CPC

- Nitrogen content in CPC

- Puffing of CPC during graphitization process

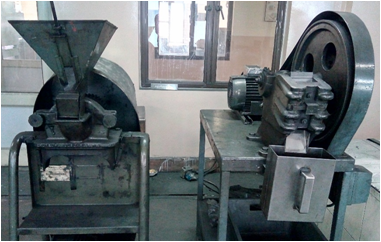

Crusher (Used for grain preparation and sizing of CPC)

Sieve Shaker (Used for grain preparation and sizing of CPC)

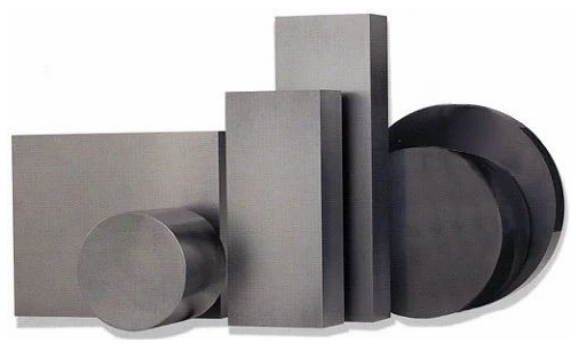

Product property measurement facilities

- Apparent Density

- Electrical Resistivity

- Flexural Strength

- Compressive Strength

- Young’s Modulus

- Energy of Fracture

- Rockwell Hardness

- Air Permeability

- Thermal Conductivity

- Coefficient of Thermal Expansion (CTE)

Eirich Mixer

Extrusion Press

Lab-scale graphite processing facilities

- Jaw Crusher – for crushing CPC

- Hammer mill – for crushing pitch

- Raymond mill – for making CPC dust

- Sieve shaker – for classification of CPC grains

- Eirich mixer – for mixing CPC and pitch to make green paste for extrusion

- Extrusion press – to extrude 50 mm dia green rods

- Baking furnace – to bake extruded sample up to 900°C at desired rate

- Graphitization furnace – to graphitize baked samples up to 2700°C at desired rate.

.

.

Graphitisation Furnace

Baking Furnace

Advanced characterization facilities

- Surface Area Analyzer – To measure specific surface area (m2/g) of activated carbon

- Mercury Porosimeter – To measure mercurial density & porosity of CPC & Graphite

- Thermo Gravimetric Analyzer (TGA) – To measure pitch volatiles and determine the rate of temperature rise in baking

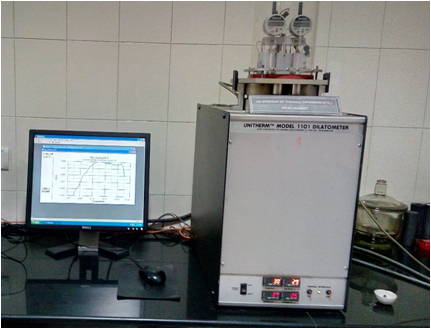

- Precision Dilatometer – To measure coefficient of thermal expansion (CTE)

- Universal Testing Machine (UTM) – To determine the flexural strength (FS) of graphite product

- X-Ray Diffractometer (XRD) – To measure the degree of graphitization and crystallite size of graphite

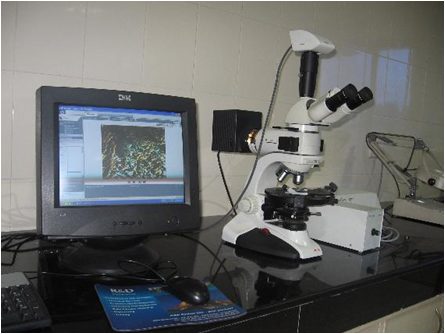

- Optical Microscope – To determine isotropic anisotropic phases in CPC, pitch and graphitized products

- Scanning Electron Microscope (SEM) – To observe structural features at sub-micron level (up to 10,000 magnification)

Surface Area Analyzer(To measure specific surface area (m2/g) of activated carbon)

Precision Dilatometer(To measure coefficient of thermal expansion (CTE))

Thermo Gravimetric Analyzer – TGA(To measure pitch volatiles and determine the rate of temperature rise in baking)

Optical Microscope Analyzer(To determine isotropic anisotropic phases in CPC, pitch and graphitized products)

Universal Testing Machine(To determine the flexural strength (FS) of graphite product)

Mercury Porosimeter(To measure mercurial density & porosity of CPC & Graphite)

X-Ray Diffractometer(To measure degree of graphitization and crystallite size of graphite)

Scanning Electron Microscope(To observe structural features at sub-micron level, up to 10,000 magnification)